Project Description

Application of Thermal Spray Techniques for Combating High Temperature Corrosion in Waste-to-Energy Boilers

Dianyi Yin, Columbia University, New York, NY

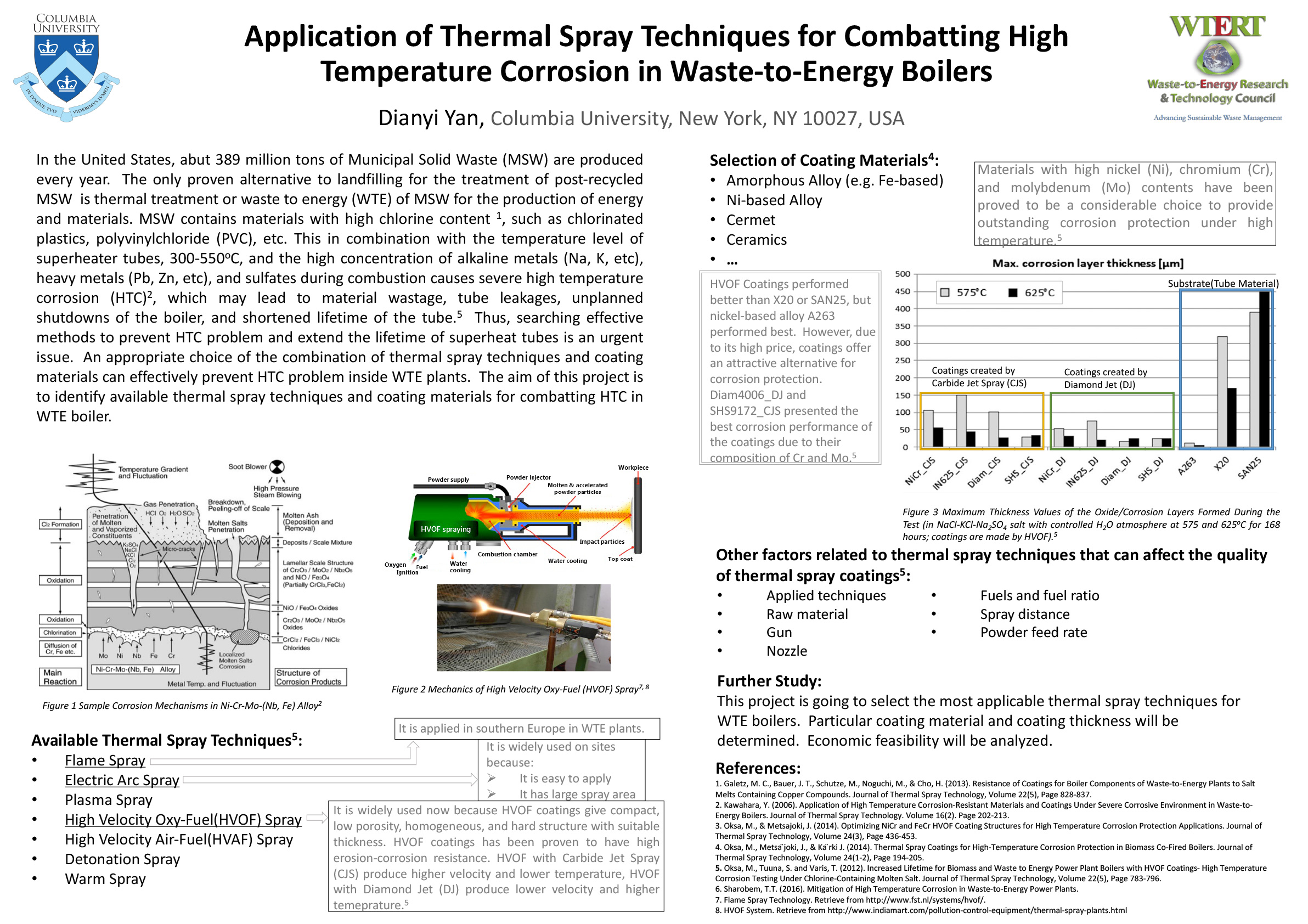

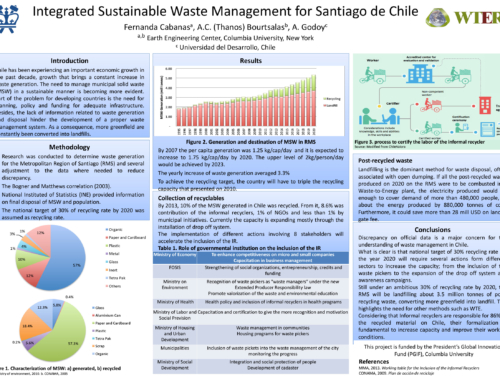

In the United States, abut 389 million tons of Municipal Solid Waste (MSW) are produced every year. The only proven alternative to landfilling for the treatment of post-recycled MSW is thermal treatment or waste to energy (WTE) of MSW for the production of energy and materials. MSW contains materials with high chlorine content, such as chlorinated plastics, polyvinylchloride (PVC), etc. This in combination with the temperature level of superheater tubes, 300-550oC, and the high concentration of alkaline metals (Na, K, etc), heavy metals (Pb, Zn, etc), and sulfates during combustion causes severe high temperature corrosion (HTC), which may lead to material wastage, tube leakages, unplanned shutdowns of the boiler, and shortened lifetime of the tube. Thus, searching effective

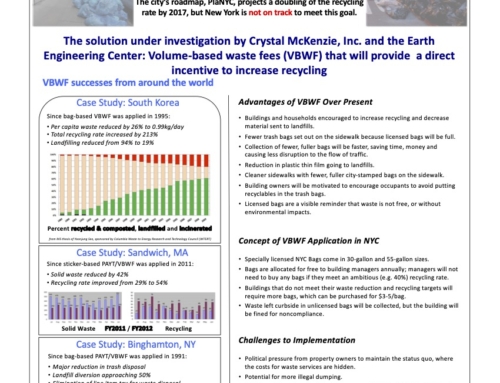

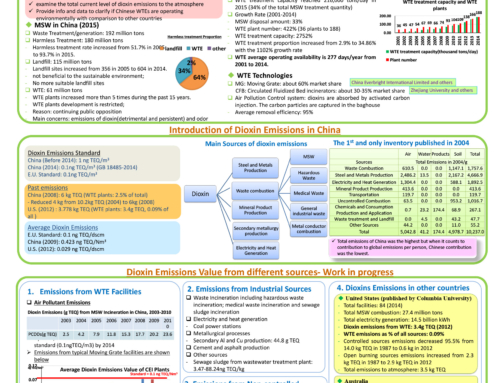

methods to prevent HTC problem and extend the lifetime of superheat tubes is an urgent issue. An appropriate choice of the combination of thermal spray techniques and coating materials can effectively prevent HTC problem inside WTE plants. The aim of this project is to identify available thermal spray techniques and coating materials for combating HTC in WTE boiler.